Przyszłość automatyzacji palenia kawy już dzisiaj!

Kompletne rozwiązanie, krótszy czas palenia!

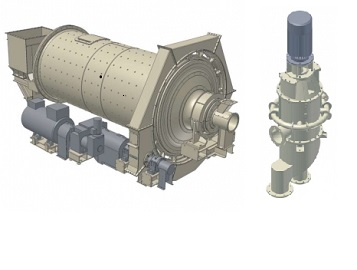

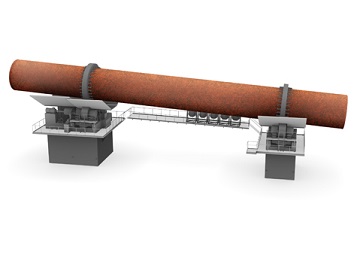

Palarki do kawy przemysłowe serii TKM – SX stanowią kompletne rozwiązanie dla hurtowych producentów i importerów kawy i ekstraktów kawy o wydajnościach do 6000 kg / h.

Seria obejmuje 7 standardowych modeli o krótszym czasie prażenia, nieograniczoną infrastrukturę PLC i automatyzacji.

Palarki kawy Toper TKM-X pracują na całym świecie od dziesięcioleci dzięki funkcjom premium i opcjom wydajności od 120 do 2000 kg / h.

5 modeli o różnych pojemnościach spełnia wszystkie wymagania produkcyjne hurtowni kawy.

Dane techniczne palarek do kawy Toper:

TKM-SX Series

| TKM-SX 30 | TKM-SX 60 | TKM-SX 120 | TKM-SX 180 | TKM-SX 240 | TKM-SX 500 | TKM-SX 1200 | |

| Light roasting capacity (kg/h) | Fast 180 Slow 90 |

Fast 360 Slow 180 |

Fast 720 Slow 360 |

Fast 1,080 Slow 540 |

Fast 1,440 Slow 720 |

Fast 2,160 Slow 1,080 |

Fast 7,200 Slow 3,600 |

| Dark roasting capacity (kg/h) | Fast 138 Slow 82 |

Fast 276 Slow 164 |

Fast 552 Slow 328 |

Fast 828 Slow 492 |

Fast 1,104 Slow 656 |

Fast 1,656 Slow 984 |

Fast 5,520 Slow 3,280 |

| Light roasting time (minutes) | Fast 10 – Slow 20 | ||||||

| Dark roasting time (minutes) | Fast 13 – Slow 22 | ||||||

| Batch capacity (kg) | 30 | 60 | 120 | 180 | 240 | 500 | 1,200 |

| Dimensions (W-H-D) cm | 271 x 295 x 225 | 310 x 368 x 303 | 443 x 340 x 412 | 381 x 342 x 520 | 570 x 350 x 387 | 412 x 352 x 621 | 1,070 x 880 x 600 |

| Recommended installation area (W-H-D) cm | 400 x 400 x 400 | 400 x 500 x 400 | 600 x 450 x 600 | 800 x 450 x 600 | – | ||

| Weight (kg) | 1,100 | 2,500 | 3,000 | 3,500 | 4,000 | 7,500 | 8,450 |

| Voltage | 240 – 380 – 415V 3PH | 380 – 415V 3PH | |||||

| Frequency | 50 – 60 Hz | ||||||

| Heat source | (Thermal Transfer) LPG – Natural Gas – Propane (Hot Air) LPG – Natural Gas – Propane – Diesel |

Diesel – LPG – Natural Gas – Propane | |||||

| Heating system | Thermal transfer or hot air flow | Hot air flow | |||||

| Number of motors | 4 | 5 | 8 | 9 | |||

| Power consumption (kW/h) | 5.5 | 10.3 | 11.8 | 15.4 | 35.5 | – | |

| Power requirement (A) | 12 | 24 | 25 | 29 | 71 | – | |

| Automation | Computerized profile roasting ready | ||||||

| Ambient temperature range (°C) | +4 / +40 | ||||||

| Gas connector (in) | 1 | ||||||

| Exhaust outlet Ø (mm) | 300 | ||||||

| Air volume requirement (m3/h) | 1,200 | 2,400 | 3,200 | 4,000 | 5,000 | 16,200 | |

| Standards | CSA ANSI Z83.11-2006/CSA 1.8-2006 Gas Food Service Equipment, MD 2006/42/EC, LVD 2006/95/EC, EN 291-1:1991, EN 292-2:1995, EN 294:1992, EN 6020-1:1997, EN 1050:1996 | ||||||

TKM-X Series

| TKM-X 30 | TKM-X 60 | TKM-X 120 | TKM-X 180 | TKM-X 240 | |

| Light roasting capacity (kg/h) | Fast 120 Slow 75 |

Fast 240 Slow 150 |

Fast 480 Slow 300 |

Fast 720 Slow 450 |

Fast 960 Slow 600 |

| Dark roasting capacity (kg/h) | Fast 100 Slow 69 |

Fast 200 Slow 138 |

Fast 400 Slow 276 |

Fast 600 Slow 414 |

Fast 800 Slow 552 |

| Light roasting time (minutes) | Fast 15 – Slow 24 | ||||

| Dark roasting time (minutes) | Fast 18 – Slow 26 | ||||

| Batch capacity (kg) | 30 | 60 | 120 | 180 | 240 |

| Dimensions (W-H-D) cm | 179 x 250 x 199 | 238 x 260 x 292 | 310 x 292 x 423 | 325 x 312 x 446 | 427 x 345 x 520 |

| Weight (kg) | 550 | 820 | 1,200 | 1,500 | 1,900 |

| Voltage | 100 – 110 – 220 – 230 – 380V | ||||

| Frequency | 50 – 60 Hz | ||||

| Heat source | Diesel – LPG – Natural Gas – LNG | ||||

| Heating system | Thermal transfer | Thermal or hot air flow | Hot air flow | ||

| Number of motors | 4 | 5 | |||

| Power consumption (kW/h) | 5.2 | 13.5 | 14.8 | 19 | |

| Power requirement (A) | 1PH 20 3PH 8.5 |

1PH 60 3PH 26.2 |

1PH 50 3PH 29 |

1PH 65 3PH 36 |

|

| Automation | Computerized profile roasting ready | ||||

| Standards | CSA ANSI Z83.11-2006/CSA 1.8-2006 Gas Food Service Equipment, MD 2006/42/EC, LVD 2006/95/EC, EN 291-1:1991, EN 292-2:1995, EN 294:1992, EN 6020-1:1997, EN 1050:1996 | ||||